The wiring harness is not only an integral part of the car, but also an important part that connects the electrical appliances and modules of the whole car, the carrier that ensures the functioning of the car, and the core hardware that ensures the comfort and reliability of the whole car. With the rapid development of automotive technology and the upgrading of automotive engine and controller chip generations, traditional LIN and CAN wiring harnesses can no longer meet the requirements of automotive signal transmission rates. HSD, FAKRA high-definition plug-ins, and special abuse wiring harness applications have emerged and are booming. Compared with traditional wire harness plug-ins, HSD and FAKRA plug-ins have more difficult requirements for high-frequency performance, so terminal crimping and processing technology are particularly important, otherwise it will affect the characteristic barrier of the product, which may lead to intermittent loss of signal, abnormal display screen of the instrument and other markets question.

1. Application and characteristics of special wire assembly

1.1 Application of special wire assembly

With the upgrade of automobile configuration, the proportion of normal use of special wire assemblies has increased, and the proportion of cost has increased accordingly. The main applications are: host to large screen (separate), 360 module to front, rear, left, and right cameras, TBOX to host, face recognition to front, rear, left, and right cameras. Taking the configuration of a self-owned brand car of about 100,000 as an example, the number of special wires is generally 10 to 15, and the proportion of the number is still very large.

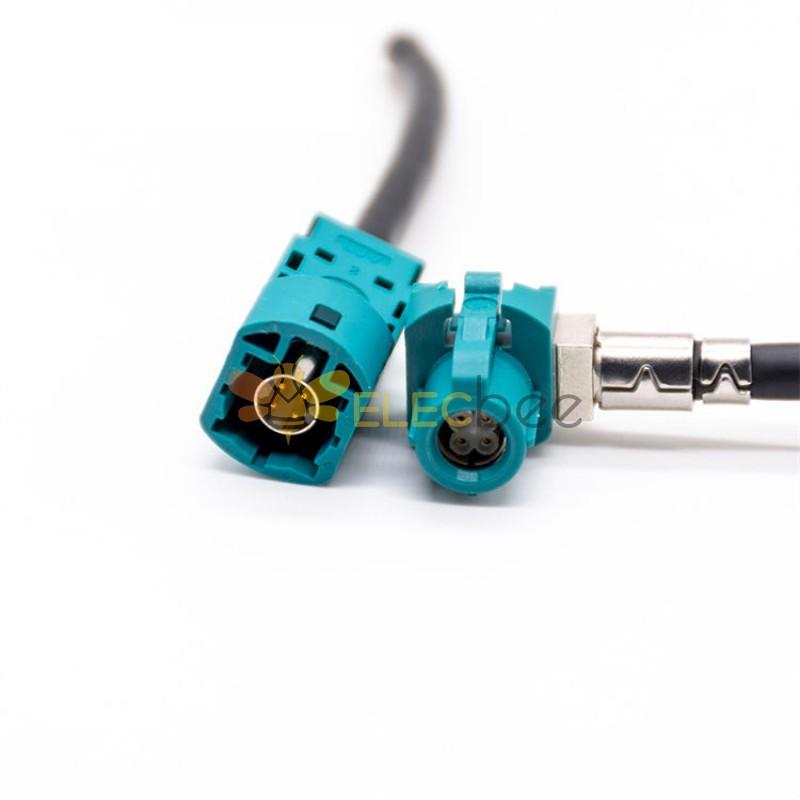

The special wire assembly is composed of high-frequency plug-ins, cables, and wrapping tape. There are two types of plug-ins: HSD and FAKRA. Among them, the mainstream foreign plug-in manufacturers include Rosenberg and Tyco, and domestic manufacturers include Xinhan and Dianlian. The interface of different brands of plug-ins is the same, but the design concepts of different manufacturers are different. Terminals, There are slight differences in the sheath physical structure. Example: The insertion and withdrawal forces of the terminals are different. For this reason, when plug-ins of different brands are used in conjunction with each other, caution is required and full verification must be done. Process control such as special wire terminal crimping and cable processing is closely related to product reliability, so the production and processing of special wires has high requirements for automation equipment.

1.2 Characteristics of special wire assemblies

Among auto parts, special wire assemblies are relatively "small parts", with relatively few secondary materials and relatively simple assembly, mainly composed of connectors and cables. According to the physical structure and transmission rate, plug-ins are divided into HSD and FAKRA. Cables are mainly divided into RG174, RTK031, RG174LL, Dacar535, Dacar636, Dacar566, etc. Different cables have different core diameters and different bending times.

HSD main performance:

1. Transmission frequency: 0-2GHz, characteristic impedance 100Ω, maximum carrying current 3A;

2. Commonly used cables: Dacar535, Dacar636 (0.14), Dacar566 (0.4), etc.;

3. Hole position: 4 PIN feet.

FAKRA main performance:

According to the size of the physical structure, it is divided into conventional FAKRA and Mini FAKRA. Compared with the regular Fakra, the Mini Fakra has a space advantage and uses a relatively small amount. There is no cost advantage to a single port. In terms of processing technology: the mainstream of conventional Fakra is the second-generation machining and the third-generation stamping. The third generation is specially designed to match the automatic production, and the cost is lower.

1. Conventional Fakra transmission frequency: 0-6GHz, characteristic impedance 50 ohms; Mini Fakra transmission frequency: 0-20GHz, characteristic impedance 50 ohms;

2. Commonly used cables: RG174 (0.14), RTK031 (0.4), etc.;

3. Hole location: 1 PIN pin for regular use, 4 PIN pins for 4-in-1 using Mini Fakra;

4. Due to bandwidth requirements, cost and other factors, except for 4-in-1 using Mini Fakra, the rest basically use ordinary Fakra.

1.3 Main characteristics of high frequency performance

The characteristic impedance is the impedance of the cable when it is infinitely long. The characteristic impedance of a cable is a complex characteristic that is determined by various physical parameters of the cable, such as inductance, capacitance, and resistance, which in turn depend on shape, concentricity, distance between conductors, and the cable's Material. Cable insulation. The characteristic impedance determines the quality of the transmission effect, and is also the key to the signal integrity problem. In addition, insertion loss, return loss, and near-end crosstalk performance, combined with temperature vibration are also key performances and are important indicators of reliability.

2. Fault analysis of special wire assembly

The special line assembly technology is relatively mature, and the product reliability is stable. The market problems caused by special wire assembly are rare, but occasionally there are. Take the occasional multimedia black and splash screen as an example for discussion. Clearly, there are a lot of issues with multimedia not displaying properly. The common reasons are abnormal BUG of the host software and damage to a single part of the large screen. The following is an introduction to the faults caused by the quality of a single cable when the functions of the host and the large screen are normal, and how to deal with the faults of the cable.

2.1 Replacement exclusion method

Occasional faults are difficult to reproduce, because faults are difficult to troubleshoot, requiring engineers to have solid theoretical knowledge and clear thinking to troubleshoot.

Conduct on-site inspection of the multimedia display system: host, large screen, wiring harness, confirm whether the surface of a single piece is damaged by "seeing", understand the working conditions and fault scenarios through "asking", and analyze potential faults through "thinking" theory combined with the fault location Reasons, clarify the troubleshooting ideas, lock the root cause, and quickly solve the fault.

Replace the main unit and the large screen with new ones in turn, and continue to run to see if the functions are normal. If necessary, conduct regular bumpy road tests to verify the quality problems of the main unit and large-screen single chip caused by chip and software bugs, and further pay attention to special wire problems.

2.2 High-frequency characteristic impedance test of faulty parts

The physical characteristics and high-frequency performance of special wire components, especially impedance and resistance, will directly affect the stability and reliability of the display system. First remove the audio and video adapter wire harness of the wire harness, and visually check whether the surface of the wire harness is damaged, whether the wire core is exposed, whether the terminal hole is abnormal, and whether it is obviously enlarged. If the abnormality cannot be completely judged, auxiliary equipment can be used to detect the faulty wiring harness. Performance, further judgment.

Characteristic impedance test equipment: impedance tester. Test method: The length of the LVDS harness is 860mm, the high-frequency parameter test uses two board-end connectors, and two PCBs dedicated to the HSD high-frequency test are welded. Test requirements: 100 ± 10 milliohms are required, if the test results exceed the required 100 ± 10 milliohms, it is the fault of the dedicated line components.

2.3 Physical characteristic test of faulty parts

Test equipment: terminal planer. Test method: Conduct cross-sectional analysis on the terminals of the faulty part. Test requirements: All crimping is qualified (there is no gap in the crimping section at the faulty part of the terminal, and the compression rate of the wire in the terminal meets the crimping requirements). If the test result: There is a hole in the crimping part of the faulty part of the terminal, the crimping is bad. For example, other common crimping failures are: crimping wings not closed, insufficient crimping, conductor end deformation, crimping wings not covering conductors, terminal crimping wings turned out, etc.

There is only one word difference between characteristic impedance and characteristic resistance, but there is an essential difference. At the same time, there is also a close relationship. Abnormal resistance leads to abnormal impedance. It can be seen that the crimping quality of the terminal directly affects the transmission performance of the terminal, and the crimping tooth length and crimping height affect the characteristic impedance, which has a great impact on product quality.

As above, replace the mainframe and the large screen in turn, simulate the operation when the fault recurs, and run a bumpy road for verification if necessary. Crimping analysis, characteristic impedance test, locking terminal crimping is not in place, resulting in different characteristic impedance, resulting in a mismatch of characteristic impedance of the display system, resulting in system abnormality.

3. Conclusion

With the improvement of the supporting facilities of the national auto industry, the improvement of laws and regulations, and the recovery of the global economy, the future auto industry will surely undergo subversive development. Assembly will be used more and more. Due to the low cost and small size of FAKRA, its general purpose will be extended. In the future, HSD may be replaced by FAKRA. At the same time, networking, intelligence, and sharing are highly integrated, and the speed and bandwidth of signal transmission between modules are required to increase. The application of 100M and Gigabit Ethernet is also the future development trend.