1.What Is an MS5015 Connector? (MIL-C-5015 Standard Overview)

The MS5015 connector, also known as a mil-spec circular connector, was originally developed under the MIL-C-5015 standard for military vehicles, aircraft, and ground support equipment.

Today, it remains one of the most widely used heavy-duty connectors thanks to its high current capacity, mechanical durability, and reliable threaded coupling.

The MS5015 design has since evolved into the modern MIL-DTL-5015 standard, offering improved performance, tighter tolerances, and expanded insert arrangements for industrial applications.

2.MS5015 Connector Specifications and Materials

MS5015 connectors are manufactured with rugged materials to ensure long-term performance in harsh environments.

Shell Materials

• Aluminum alloy (lightweight, corrosion-resistant)

• Stainless steel (high-strength, extreme environments)

• Brass / copper alloys

Insulator Options

• Rubber

• Synthetic rubber

• Thermoplastic

• Glass-filled materials

Contact Materials

• Copper

• Copper alloys

• Nickel, alumel

• Custom alloys for high-temperature or special applications

Typical Electrical Specifications

• Current rating: up to 150A (depending on size & contacts)

• Voltage: up to 3000V

• Temperature range: –55°C to +125°C

• Contact resistance: low, optimized for stable signal transmission

• Environmental sealing: Available with IP67/IP68 variants

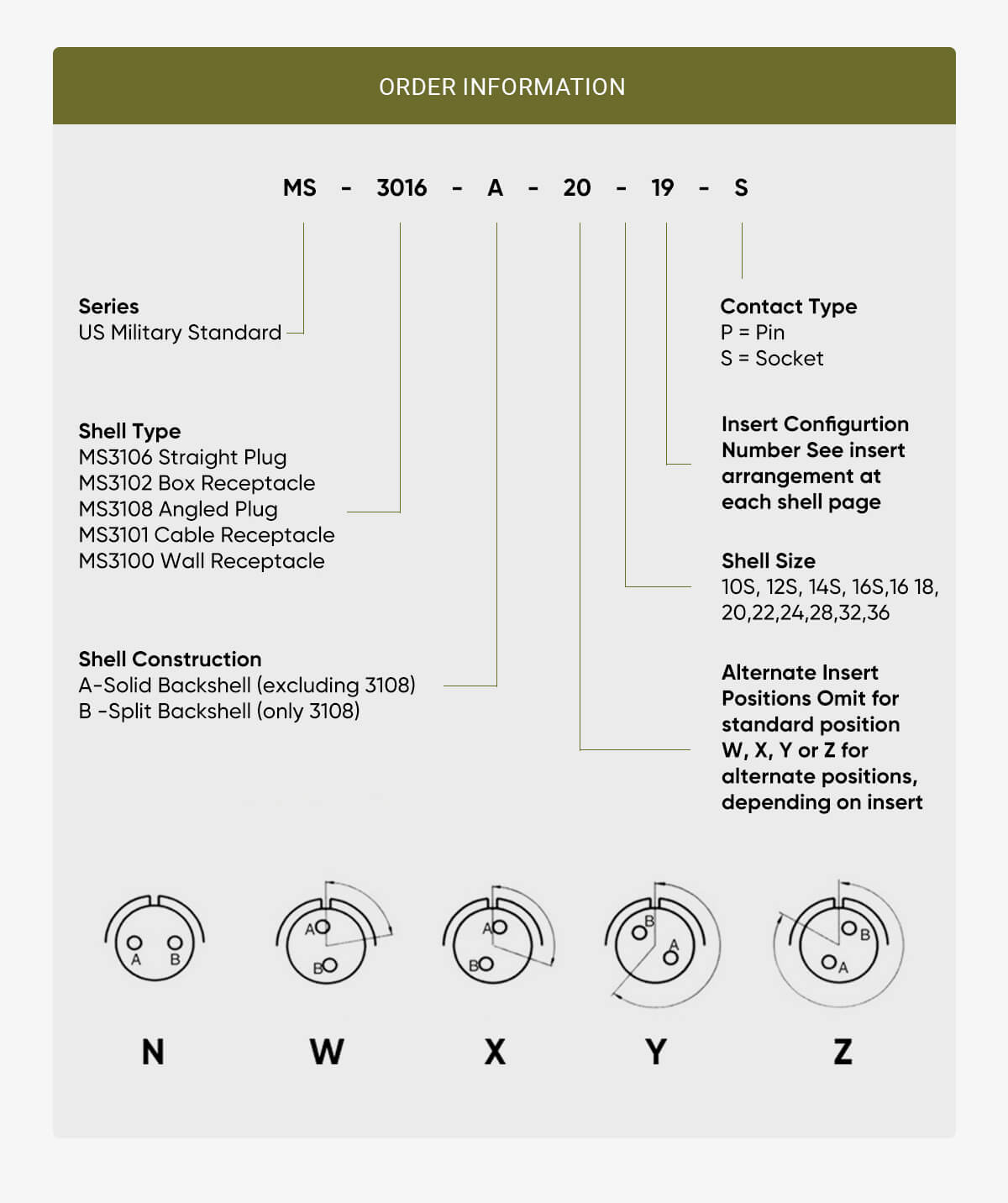

3.MS5015 Connector Styles, Shell Sizes and Pin Configurations

MS5015 connectors provide one of the largest insert pattern selections in the industry.

Shell Styles

• Plug / receptacle

• Straight and 90-degree elbow

• Wall-mount, box-mount, jam-nut receptacles

Shell Sizes (Common Sizes)

8S, 10S, 10SL, 12S, 14S, 16, 18, 20, 22, 24, 28, 32, 36, 40, 44, 48

Insert Patterns

• Over 300 pin configurations

• Power-only, signal-only, or mixed power/signal

• Coaxial and thermocouple contacts available

4.Key Features and Performance Advantages

• Threaded coupling for vibration resistance

• Environmental sealing for outdoor and industrial use

• Mixed contact capability (power + signal)

• RoHS-compliant plating options

• Filtering receptacle options for EMI/RFI protection

• Compatible with multiple manufacturers following MIL-DTL-5015

5.MS5015 Applications in Military and Industrial Systems

Although originally designed for aircraft, MS5015 connectors are now widely used in:

• Military vehicles and ground systems

• Industrial machine tools

• Heavy equipment and construction machinery

• Medical devices

• Servo motors & robotics

• Marine equipment

• Power distribution and control systems

Their combination of durability, high current handling, and broad compatibility makes them ideal for both legacy systems and modern industrial automation.

6.How to Select the Right MS5015 Connector

When choosing an MS5015 connector, consider:

a. Shell size & insert pattern

Select based on required pin count and current capacity.

b. Coupling method

Threaded vs bayonet (bayonet for faster mating/unmating).

c. Environmental requirements

Choose sealed versions for outdoor, marine, or dusty environments.

d. Contact type

Power, signal, coaxial, or thermocouple.

e. Material & plating

For corrosion-prone environments, stainless steel or special plating is recommended.

7.MS5015 vs Other Mil-Spec Connectors

|

Feature |

MS5015 |

MIL-DTL-26482 |

MIL-DTL-38999 |

|

Coupling |

Threaded |

Bayonet |

Quick-disconnect triple-start |

|

Density |

Medium |

Medium |

High-density |

|

Strength |

High |

Medium |

Very high |

|

Typical use |

Power / mixed |

Industrial automation |

Aerospace / high-vibration |

|

Cost |

Low–Medium |

Medium |

High |