1.What Is a Pin Header Connector?

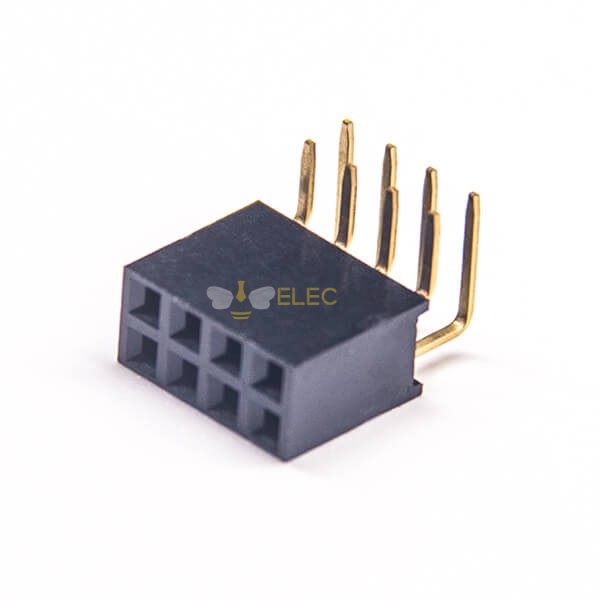

A pin header connector, also known as a PCB header, is a type of electrical connector featuring one or more rows of male pins. These connectors are widely used to provide reliable connections between PCBs, modules, or cable harnesses. When mated with a female header, pin headers form a secure board-to-board or board-to-wire connection for signal and power transmission.

2.Common Types and Sizes of Pin Headers

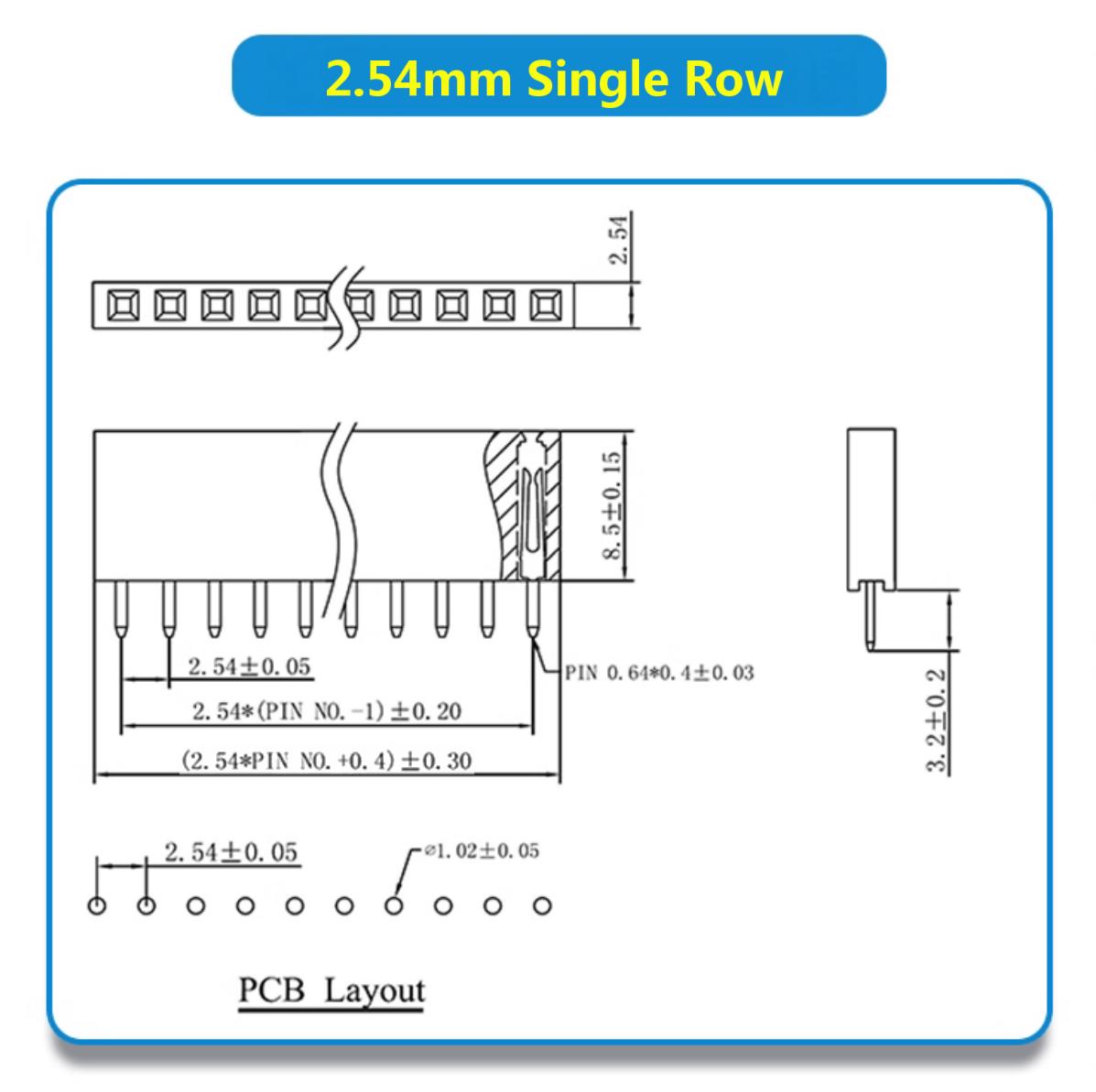

Pin headers come in various pitches (pin spacing) and mounting styles to suit different PCB layouts.

Typical sizes include 0.8mm, 1.0mm, 1.27mm, 2.0mm, and 2.54mm, with 2.54mm being the most common.

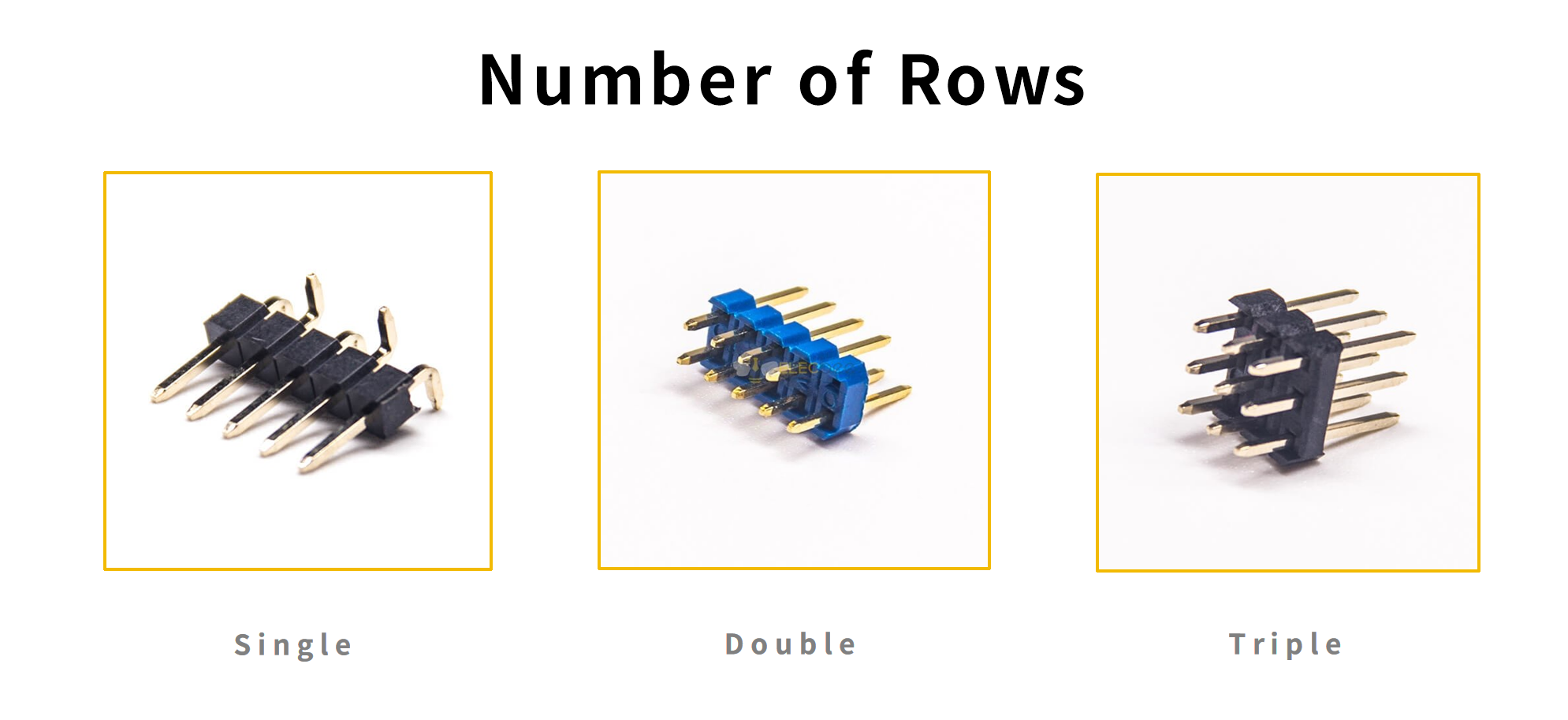

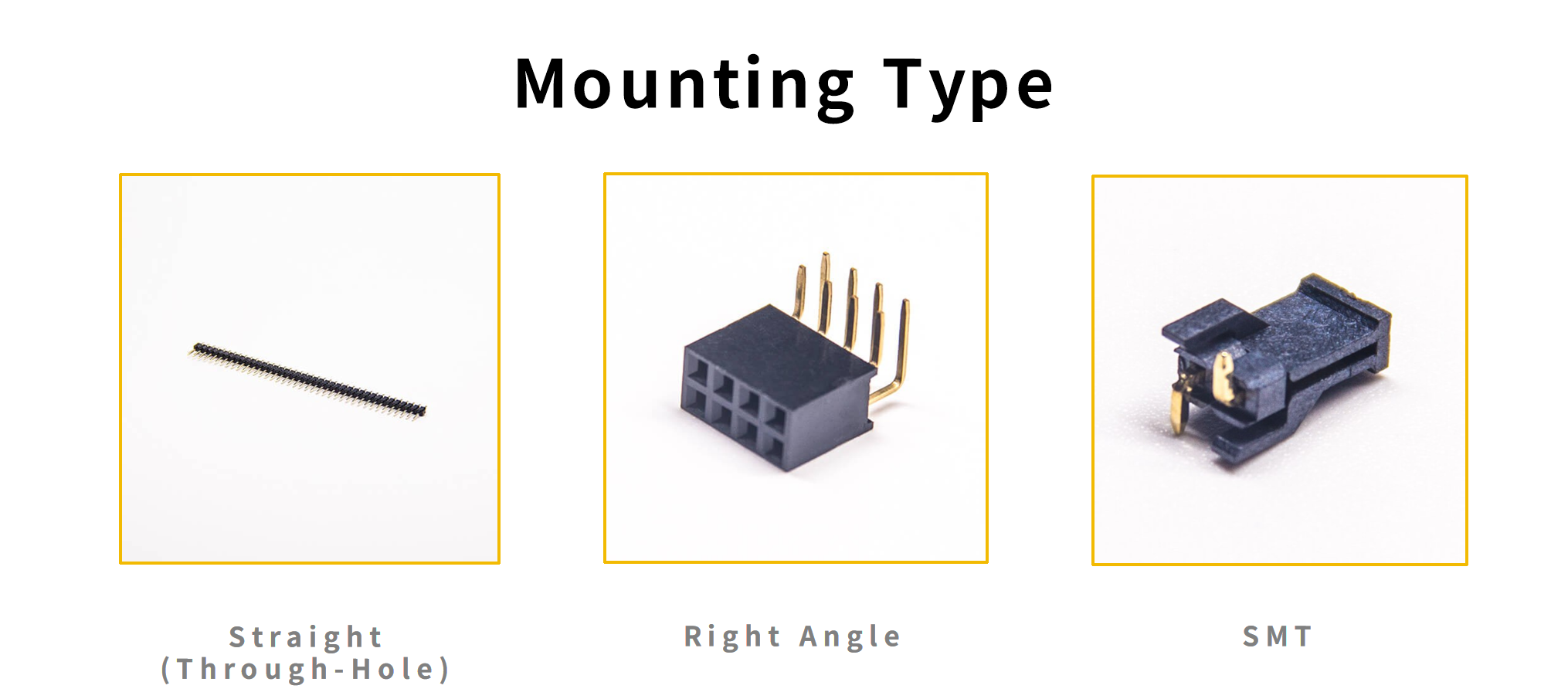

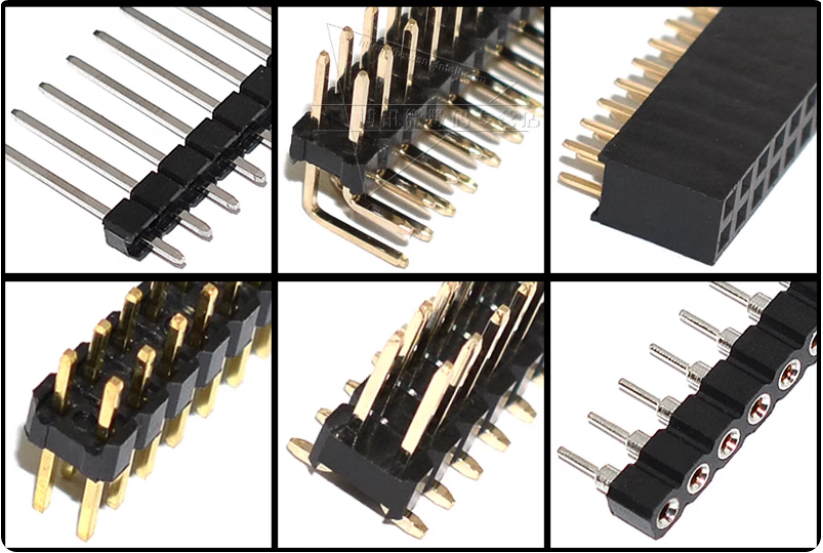

By structure, pin headers can be:

• Single Row / Double Row / Triple Row / Quad Row

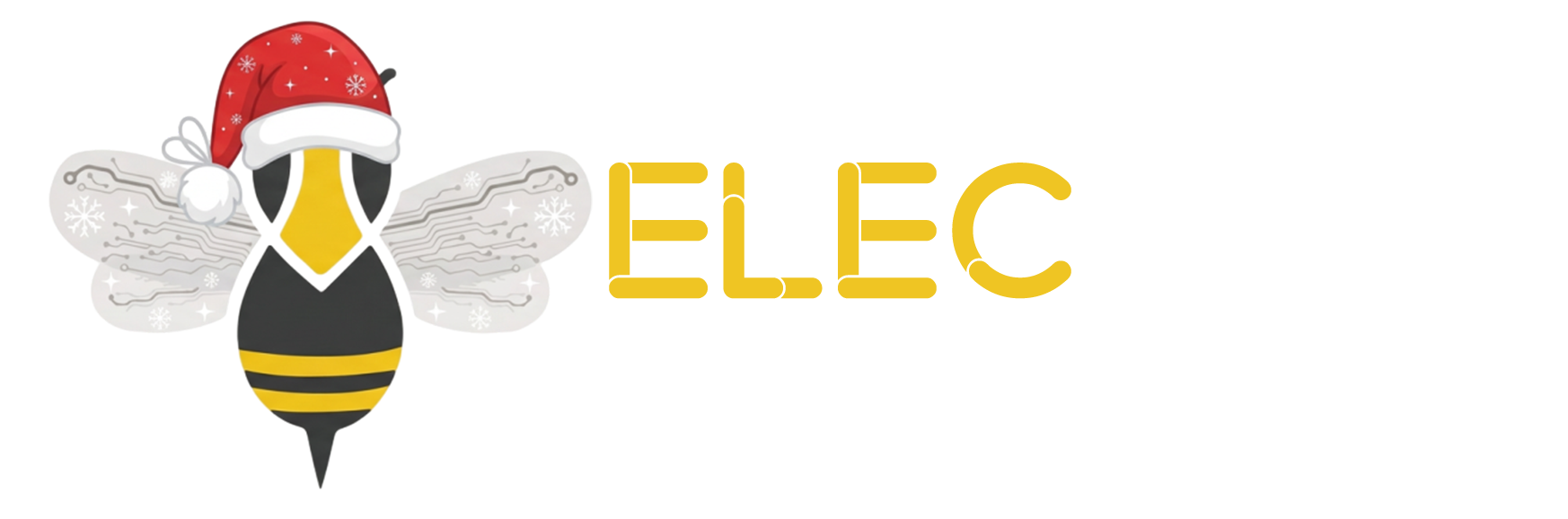

• Straight (Through-Hole), Right Angle, or SMT (Surface Mount)

By plastic height: single, double, or triple plastic insulators are used depending on design requirements.

3.Materials and Plating Options Explained

Pin Materials: Brass or phosphor bronze for optimal conductivity.

Insulator Materials: High-performance plastics such as PBT, PA46, PA66, or LCP, rated UL94V-0 for flame resistance.

Surface Treatments:

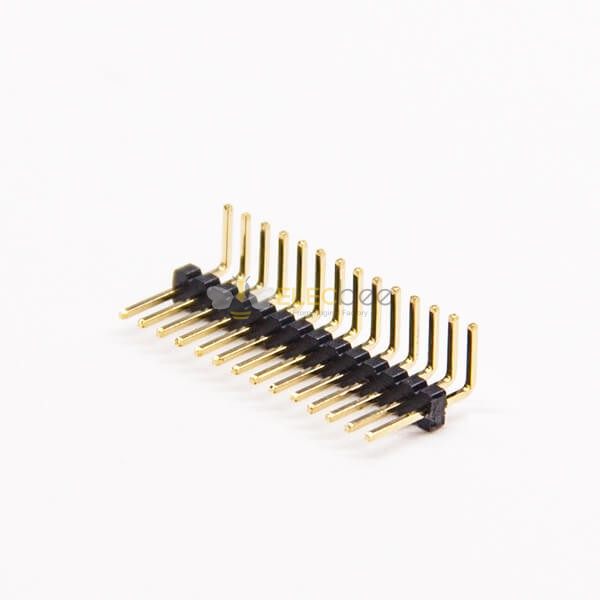

• Gold plating (various thicknesses such as 0.8U” or thicker)

• Tin or nickel plating

Why plating matters: Gold plating enhances corrosion resistance and long-term signal reliability—ideal for precision electronic applications.

4. Applications of Pin Header Connectors in Electronics

Pin headers are used across a wide range of industries and products:

• Consumer Electronics: Smart home devices, displays, audio systems

• Automotive Electronics: Control modules, dashboards, sensors

• Industrial Equipment: PLC systems, servo controllers, test devices

• IoT Devices: Development boards, data transmission modules

These connectors act as bridges between isolated circuits, ensuring consistent signal and current transmission.

5.How to Choose the Right Pin Header for Your PCB

When selecting a pin header, consider:

a. Pitch size: Match with your PCB layout (e.g., 2.54mm for standard applications).

b. Mounting type: Straight, right-angle, or SMT based on assembly requirements.

c. Material and plating: Gold for high-reliability or nickel for cost efficiency.

d. Current rating: Ensure pins support your voltage and current needs.

e. Mating connector type: Confirm compatibility with the matching female header or wire harness.

Pro tip: For industrial or high-vibration environments, choose gold-plated or locking-type headers for enhanced reliability.

6.FAQ: Common Questions About Pin Headers

Q1: Can I use a 2.54mm pin header with a 2.0mm socket?

No, mismatched pitch sizes can lead to poor contact and damage.

Q2: What is the best plating for long-term use?

Gold plating provides the best corrosion resistance and stability for low-current signals.

Q3: Can pin headers be customized?

Yes, Elecbee offers both standard and custom pin headers in 0.8–2.54mm pitch for specific PCB applications.

7.Conclusion

Pin header connectors remain one of the most versatile and cost-effective interconnection solutions in modern electronics. Whether used for prototyping or mass production, choosing the right type, material, and plating ensures durability and performance.

Need custom pin headers for your design?

Explore Elecbee's Headers, Receptacles for compatible solutions.